What are the different phases of the C&Q process in India?

The C&Q process in India encompasses Planning, Design, Installation, Operational, and Performance Qualification phases. Each phase involves meticulous planning, execution, and validation to ensure compliance with regulatory standards and the smooth functioning of pharmaceutical facilities.

What are Pharmaceutical Commissioning and Validation Checklist in India?

Pharmaceutical Commissioning and Validation Checklists in India are comprehensive tools that cover equipment, systems, and processes. These checklists play a crucial role in ensuring that pharmaceutical facilities adhere to regulatory guidelines, encompassing everything from equipment calibration to documentation protocols.

What are the Factors to Consider When Choosing a Commissioning Service Provider in India?

When selecting a Commissioning Service Provider in India, factors such as extensive experience, specialized expertise, in-depth regulatory knowledge, and a proven track record in the pharmaceutical industry are critical. These factors ensure that the chosen service provider can navigate the complexities of commissioning with precision.

What are the Benefits of Using Commissioning Services for Pharmaceutical Industry in India?

Commissioning services in the pharmaceutical industry offer multifaceted benefits, including heightened compliance assurance, risk mitigation, enhanced operational efficiency, and the validation of performance metrics. Engaging these services is a strategic move to uphold quality standards and streamline pharmaceutical processes.

How to Ensure Successful Commissioning of a Pharmaceutical Facility in India?

Successful commissioning of a pharmaceutical facility in India requires meticulous planning, the engagement of experienced professionals, and strict adherence to regulatory guidelines. Rigorous testing, documentation, and collaboration between stakeholders contribute to the seamless integration of systems and processes.

What are the Common Challenges Faced During the Commissioning of Pharmaceutical Facilities in India?

Challenges during pharmaceutical facility commissioning often revolve around integration issues, documentation complexities, and unexpected technical hurdles. Addressing these challenges demands a proactive approach, effective communication, and the ability to adapt to unforeseen circumstances.

What are the Regulatory Requirements for Commissioning of Pharmaceutical Facilities in India?

Regulatory requirements for commissioning in India involve compliance with national regulatory authorities such as the Central Drugs Standard Control Organization (CDSCO) and adherence to World Health Organization Good Manufacturing Practices (WHO-GMP) guidelines. Meeting these standards is paramount for ensuring the quality and safety of pharmaceutical products.

What are the Future Trends in Commissioning Services for Pharmaceutical Industry in India?

The future of commissioning services in the Indian pharmaceutical industry is marked by a shift towards increased automation, digitalization, and a growing emphasis on sustainability. The integration of advanced technologies and eco-friendly practices reflects the industry’s commitment to innovation and environmental responsibility.

What are the Expert Tips for Commissioning Pharmaceutical Facilities in India?

Expert tips for commissioning pharmaceutical facilities include the engagement of seasoned professionals, prioritizing meticulous documentation, and conducting thorough testing and validation processes. Collaboration, attention to detail, and a commitment to excellence are key factors in achieving successful commissioning outcomes.

What are the latest regulatory trends in pharmaceutical C&Q in India?

Current regulatory trends in pharmaceutical C&Q in India underscore the importance of data integrity, the implementation of risk-based approaches, and a focus on continuous process verification. Staying abreast of these trends is vital for companies aiming to align their practices with evolving regulatory standards and industry best practices.

How can pharmaceutical companies stay up-to-date on C&Q regulatory requirements in India?

Pharmaceutical companies can stay up-to-date on C&Q regulatory requirements in India by actively monitoring regulatory updates, participating in industry forums and conferences, and engaging experienced consultants. This proactive approach ensures that companies are well-informed and can swiftly adapt to changes, maintaining compliance and quality standards.

What exactly do Commissioning Services entail for pharmaceutical companies?

Commissioning Services go beyond mere equipment installation and validation.

We ensure your entire production plant, systems, and processes are brought online smoothly and efficiently, transitioning from construction to consistent, high-quality manufacturing. This includes:

Developing Commissioning Plans: Tailored plans addressing all aspects of equipment setup, testing, validation, and operator training.

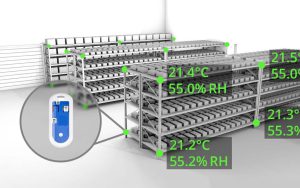

Managing Equipment Start-up: Overseeing the safe and proper installation, calibration, and initial operation of all equipment.

Process Validation and Optimization: Performing comprehensive qualification procedures to verify your processes meet required specifications and optimize performance.

Documentation and Reporting: Creating detailed reports and protocols throughout the commissioning process, ensuring compliance and operational readiness.

Operator Training and Support: Providing training programs for your team on the safe and efficient operation of new equipment and processes.

How can effective Commissioning Services benefit my pharmaceutical company beyond smooth start-up?

Minimized Production Delays and Costs: Our structured approach identifies and resolves potential issues early, preventing costly downtime and delays in reaching full production capacity.

Enhanced Product Quality and Consistency: Optimized processes and validated equipment contribute to the reliable production of high-quality pharmaceutical products.

Reduced Regulatory Risks and Compliance Issues: Thorough documentation and validated procedures minimize the risk of non-compliance fines and regulatory delays.

Improved Operational Efficiency and Control: Streamlined processes and trained operators result in smoother production runs, increased throughput, and reduced operational costs.

Instead of experience and expertise, what specific questions should I ask potential Commissioning Service providers?

It’s important to delve deeper than just experience and expertise. Here are some key questions to ask potential Commissioning Service providers:

Track record in the pharmaceutical industry: Do they have specific experience with projects similar to mine, including equipment types and regulatory requirements?

Project management approach: How do they ensure clear communication, collaboration, and timely project delivery?

Risk mitigation strategies: What processes do they have in place to identify and address potential risks early during commissioning?

Quality assurance procedures: How do they ensure documented procedures, data integrity, and compliance with regulatory standards throughout the process?

Post-commissioning support: What level of ongoing support and assistance do they offer after the initial commissioning is complete?

How do you tailor your Commissioning Services to my specific needs and equipment?

We collaborate closely with your team to understand your unique processes, equipment configurations, and regulatory requirements.

This ensures our commissioning plan is customized to address your specific challenges and optimize your production lines.

What happens after the commissioning process is complete?

We remain available to your team for ongoing support and consultation. We can provide post-commissioning assistance with troubleshooting, process optimization, and regulatory compliance guidance, ensuring the continued smooth operation of your pharmaceutical production facility.